News & Presse

Sustainable composites

18.10.2022

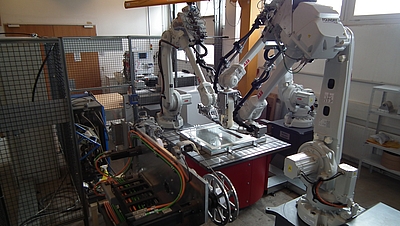

At the Transfer Centre for Plastics Technology in Wels, experts are working on fibre-reinforced plastics for lightweight construction. Sustainability and recycling are the future focal points. Research is being conducted on innovative recycling solutions for customers who can also have their materials and components tested.

Innovative surface coating

06.10.2022

The RUBIG Group is consolidating its Laser Technology and Surface Coating divisions with its latest subsidiary, RUBIG Technology. This increases the field of application for lightweight parts at the same time. The surface coating technology is individually adapted to the customer‘s requirements. And RUBIG has even found a formula to fight viruses and bacteria.

Innovation in composites

21.09.2022

Peak Technology GmbH‘s products launch rockets into space, move satellites into the right orbit, propel formula 1 cars, electrify air travel, store hydrogen, and win the 24 Hours of Le Mans. It is the challenge that drives the Upper Austrian lightweight construction specialist.

Research on lightweight technology

07.09.2022

The Polymer Competence Center Leoben GmbH (PCCL) is a collaborative research institute focusing on polymer science and technology. Hereby, the main focal points are polymer based, functional and structural materials as well as production and processing technologies. These are intended as the basis for future innovations in a wide range of applications.

KVT eröffnete sein Experience Center offiziell am 30.06

05.09.2022

Am 30.06. wurde das KVT Experience Center offiziell eröffnet. Kunden, Lieferanten und Geschäftspartner wurden in das Gebäude des Experience Centers in Linz eingeladen.

MAST3RBoost

Neuartige Wasserstofftanks als Beitrag zur Dekarbonisierung des Verkehrssektors

02.09.2022

MAST3RBoost (Maturing the Production Standards of Ultraporous Structures for High Density Hydrogen Storage Bank Operating on Swinging Temperatures and Low Compression) ist ein europäisches Projekt, das darauf abzielt, durch die Entwicklung einer neuen Generation von ultraporösen Speichermaterialien (Aktivkohlen/ACs und metallorganische Gerüstverbindungen/MOFs) für wasserstoffbetriebene Fahrzeuge (Straßen- und Schienenverkehr, Luft- und Wassertransport) eine industrie-taugliche Lösung für die H2-Speicherung bei kryogener Speichertemperatur (~-180°C) unter Kompression (100 bar) zu schaffen.

Leichtbau ist ökonomisches Schwergewicht und Schlüssel für den Klimaschutz

Studie zeigt erstmals wirtschaftliche Bedeutung von Leichtbau-Technologien in Österreich

01.09.2022

Es gibt kaum Technologien mit vergleichbarer Wirkung, doch wird sie als eigene Disziplin kaum wahrgenommen: Leichtbau ist eine Antwort auf Material- und Energieknappheit und damit eine Schlüsseltechnologie für den Klimaschutz. Leichtbau ist darüber hinaus ein Stärkefeld österreichischer Unternehmen und Forschungseinrichtungen, das schon jetzt für eine Wertschöpfung von 9,4 Mrd. Euro sorgt und 77.400 Arbeitsplätze sichert. Auch für die Zukunft verspricht es weiteres Wachstum. Zu diesem Ergebnis kommt eine erstmals durchgeführte Analyse der Ökonomin Anna Kleissner im Auftrag der österreichischen Leichtbauplattform Austrian Advanced Lightweight Technology (A2LT).

A success story, since 1985

24.08.2022

With high tech, high speed and high quality, Pankl Racing Systems has been one of the world‘s leading developers and producers of engine, chassis and drivetrain components since 1985. Pankl not only supplies the racing industry, but also the sports car and aviation industries with innovative products.

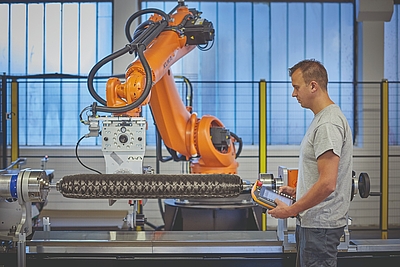

Lightweight polymer construction

10.08.2022

The Montanuniversität Leoben (University of Leoben) works on polymer lightweight construction for various differnt fields of application with a sound understanding of the materials, micro- and macromechanical modelling expertise and on the basis of broadly based processing technology.

Lightweight cylinders for everyone

27.07.2022

The MARK Group looks back on an innovation track record that goes back nearly 100 years. The company revolutionised skiing with the invention of the ski boot buckle. By entering the automotive market, MARK Hydraulik GmbH created the basis for sustainable entrepreneurial activity and the foundation for the on-going development of groundbreaking technologies and products.